O que é um sistema de luz hidropônica e por que é essencial para a agricultura vertical?

Funções essenciais de um Sistema de Luz Hidrónica na Agricultura Controlada

Um sistema de luz hidropônica é um sistema de iluminação feito para ajudar o crescimento das plantas em áreas geridas sem solo. Esses sistemas desempenham um papel fundamental na agricultura vertical. Eles copiam as plantas de luz solar necessárias para fotosíntese. Isso permite que as culturas crescam dentro. Ao dar certos comprimentos de onda de luz, a iluminação hidropônica assegura que as plantas obtêm a energia certa para cada passo de crescimento. Isto passa de sorrir para florar.

Em áreas de agricultura vertical onde a luz natural é baixa ou falta, a iluminação falsa atua como a principal fonte de energia para o crescimento das plant as. A chance de estabelecer tempo de luz, força e cor permite aos produtores aumentar a produção todo o ano. Isso funciona independentemente do tempo externo.

Benefícios do uso de iluminação inteligente em explorações urbanas verticales

Sistemas inteligentes de luz hidropônica dão ganhos claros para as fazendas verticais urbanas. Elas melhoram o trabalho, precisão e práticas verdes. Esses sistemas permitem controles remotos e mudanças. Os agricultores podem definir tempos e forças de iluminação usando plataformas principais ou aplicativos telefónicos.

Este tipo de controle corta a perda de energia. Plantas recebem a luz necessária nos momentos certos. Além disso, iluminação inteligente ajuda até mesmo a cultivar crescimento em muitos níveis. Este é um ponto principal para manter qualidade e produção constantes em pontos de crescimento urbano.

O papel do espectro de luz e da intensidade no crescimento das plantas

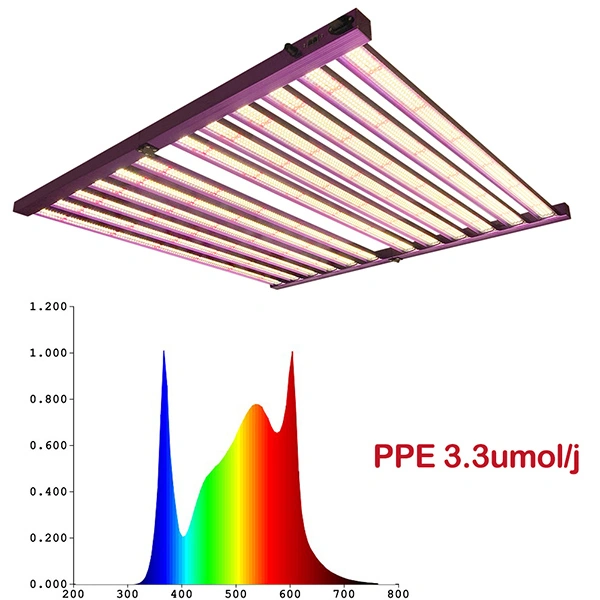

O trabalho de um sistema de luz hidropônica depende de sua habilidade de dar a cor e for ça certas para a planta’ as necessidades. Luzes LED de espectro completo são comuns. Eles copiam luz solar natural e incluem todos os comprimentos de onda chave.

A chave para seu sucesso está no seu espectro completo, o que garante que suas plantas recebem a quantidade e qualidade adequadas de luz em todos os estágios do crescimento. Desde a fase vegetativa até a flor, ele fornece o espectro de luz necessário para maximizar rendimento e produção.

Os níveis de alta densidade de fluxo de fóton também importam. Eles estabelecem quanta luz útil atinge superfícies vegetais. Por exemplo, TIDESTAR 1000w Full Spectrum 5x5ft Samsung lm301H Foldable Plant LED Grow Lights oferecem um PPFD impressionante de 3300 μmol/s com uma avaliação de eficiência até 3,34 μmol/J, tornando-os ideales para ambientes cultivos de alta densidade.

Como as características inteligentes melhoram os sistemas de luz hidropônica nas configurações urbanas?

Capacidades de Automatização e Monitorização em tempo real

Sistemas de iluminação hidropônica inteligentes se misturam em partes de automatização. Esses deixam os cultivadores estabelecer tempos de iluminação baseados nas necessidades de luz das colheitas. Essas características cortam o trabalho de mão. Eles aumentam a estabilidade durante as rondas de crescimento.

As habilidades de verificação em tempo real também acrescentam ao controle. Eles dão visões sobre o trabalho do sistema e condições de área como temperatura ou umidade. Os avisos podem começar se problemas acontecem. Isso ajuda a impedir a perda de culturas de calor demais ou luz demais.

Integração com IoT Devices and Farm Management Software

Novos sistemas de luz hidropônicos funcionam bem com dispositivos de Internet-of-Things (IoT) e software de controle agrícola. Esta mistura torna fácil compartilhar dados entre peças de iluminação, sensores, sistemas nutrientes e ferramentas climáticas.

Ao trazer esses dados para uma tela principal, os líderes da agricultura podem fazer escolhas inteligentes. Elas melhoram o uso de recursos e aumentam a saúde das culturas. Isso conectado apoia maneiras de agricultura exatas. Esses são básicos para um bom trabalho de agricultura vertical.

Eficiência energética e controles ambientais em sistemas inteligentes

A poupança de energia é uma parte principal de sistemas inteligentes de iluminação hidropônica. Muitos sistemas usam luzes LED ajustadas. Essas mudanças de brilho baseadas em feedback sensorial ou tempo definido.

- Controlo Dimmer: Adjuste a intensidade da luz para atender às necessidades específicas das plantas, melhorando o controle e a adaptabilidade. Cada LED tem uma característica mais obscura, bem como uma característica de cadeia de doces.

- Operação Silenciosa: Alimenta suas plantas em um ambiente tranquilo graças ao sistema de refrigeração silencioso e sem ventiladores.

Além disso, sistemas de controle de calor sem ventiladores afastam o calor das plantas. Eles fazem isso sem fãs ruidosos. Isso mantém economia de energia e trabalho tranquilo em fazendas urbanas fechadas.

Por que sistemas de luz hidropônicos são críticos para a eficiência agrícola vertical urbana?

Optimização do espaço através de estratégias de iluminação alvo

As fazendas urbanas geralmente funcionam em pequenas áreas. Cada metro quadrado deve funcionar bem. Um sistema de luz hidropônica ajuda o uso do espaço dando luz direta sobre os topos das plantas. Usa barras ou painéis móveis.

Sua potência e eficiência fazem dela ideal para 150 x 150 cm de espaços de crescimento, fornecendo cobertura óptima e uniforme para todas as suas plantas. Essa extensão exata corta luz perdida. Isso assegura-se de atingir vários níveis. Isso é chave para aumentar a produção por área.

Consistencia e confiabilidade nos ciclos de produção de culturas

Um grande ganho de usar melhores sistemas de iluminação é sua estabilidade em longos períodos. A vida típica é de 50.000 horas para que a produção de luz caia para 70% do nominal. Isso assegura que as culturas tenham luz constante durante muitas rondas de colheita. Faz isso sem muitas vezes mudar ou exigir paradas de manutenção.

Tal trabalho duradouro ajuda a produções constantes. Essa é uma necessidade principal de fazendas urbanas de negócios que fornecem mercados locais em pouco tempo.

Reduzir os custos laborais e operacionais com iluminação inteligente

Luzes hidropônicas inteligentes cortam as necessidades dos trabalhadores. Eles fazem isso colocando tarefas como mudanças de brilho ou tempo de luz sozinhos. Eles também baixam os custos de funcionamento com tecnologia de poupança de energia. Isto usa muito menos energia do que velhas lâmpadas HID.

Eficiente em Energia: reduzir os custos energéticos ao proporcionar luz poderosa e intensa, promovendo crescimento sustentável. Quando misturados em configurações de automatização mais amplas, incluindo o controle da água, essas luzes ajudam a desviar o trabalho. Eles elevam os limites de lucro.

Como você pode implementar um Smart Hydroponic Light System em sua fazenda urbana?

Planificar a disposição de iluminação baseada no tipo e estrutura de corte

Uma boa configuração começa com um planejamento cuidadoso colocado em torno dos tipos de culturas (verdes folhosos contra plantas de fruta) e montagens de rack (uma camada contra muitas). Coisas como altura de montagem (altura de montagem: ≥15 cm acima das pontas da planta) devem ser pensadas durante a colocação. Isto é para o melhor PPFD espalhado em todos os níveis de folhas.

Os crescedores também deveriam escolher cores baseadas em objetivos de crescimento. Usar cores azuis-pesadas em estágios de folhas ou cores reforçadas com vermelho em fases de flor. Isso encaixa os resultados às necessidades.

Requisitos de conectividade para funcionalidade inteligente

Para usar habilidades inteligentes inteiramente, a conexão deve estar de volta sem fio formas de conversa como Wi-Fi ou Zigbee. Também deveria ter partes de controle correspondentes. Muitas luzes novas vêm com portos integrados ou unidades sem fio. Isso faz uma mistura fácil em redes de fazenda atuais sem dificuldades de reembolso.

Certificar-se de que se encaixa com o atual software de controle da fazenda irá suavizar a colocação. Ela aumenta o retorno em gastar através de uma supervisão sobre todas as partes. Isto inclui iluminação, água, controle de temperatura e mais.

Mantenimento, Calibração e Optimização do Performance a longo prazo

Mantenimento normal significa limpeza de lentes ou painéis. Isto impede a construção de poeira que pode diminuir a produtividade ao longo do tempo. A configuração regular assegura que os níveis de PPFD estão em zonas diferentes em sua configuração. Isso é chave quando cresce trabalho em muitas áreas ou salas.

Dada sua longa vida (Vida: > 54.000 horas), sistemas de LED de alta qualidade requerem uma manutenção mínima, mas beneficiam de inspecções programadas alinhadas com ciclos de colheita ou transições sazonais para uma continuidade de desempenho óptima.

Como o TIDESTAR’ s Soluções Avançadas do Sistema de Luz Hidrónica para a Agricultura Vertical?

Quem Somos: Introduzir TIDESTAR’ Missão e Expertização

Em TIDESTARfocamos em fazer um trabalho alto LED cresce luzes para usos de agricultura vertical. Nosso objetivo é ajudar os cultivadores com novas tecnologias. Isso aumenta a produção ao mesmo tempo que apoia formas verdes através de bom uso de energia e peças de design inteligente.

Misturamos habilidades técnicas com vistas reais de produtores de negócios em todo o mundo. Isso assegura que nossas reparações enfrentam desafios diários em fazendas urbanas modernas. Esses limites de espaço ou pressões de regra.

Nossos produtos emblemáticos para as fazendas urbanas verticais

Nosso produto principal, o TIDESTAR 1000W LED PRO, é feito com especificações pro-níveis. Tem alto fluxo de fóton PPF e boa eficiência at é 3,3 µmol/J. Sua cobertura de espectro completo usa chips Samsung LM301H (3000K/5000K) com diodos vermelhos de Osram a 660NM. Isso assegura um trabalho forte desde a semente até a colheita.

Com classificação de localização húmida IP65, design passivo de refrigeração térmica, estrutura dobrável para necessidades compactas de armazenamento/transporte – e compatibilidade entre padrões de tensão globais – representa uma escolha ideal para ambas as empresas iniciais escalando rapidamente ou estabelecidos produtores actualizando legais configurações.

Por que TIDESTAR’ s Sistema É Ideal para Ambientes Urbanos

Os locais urbanos precisam de pequenas, mas fortes reparações. Isso dá resultados constantes em condições de mudança. Os produtos TIDESTAR são fáceis de instalar, o calor direcionado para cima longe das plantas, e obscura, tornando-as perfeitamente adequadas para espaços interiores estreitos onde o fluxo de ar pode ser limitado mas as expectativas de desempenho permanecem altas.

Sua modularidade permite a integração sem problemas em sistemas de escala comuns em estufas urbanas – oferecendo soluções escaláveis apoiadas por padrões de construção duradouros (> 50 mil horas de vida), assegurando a viabilidade a longo prazo mesmo em cenários de uso intensivo típicos de operações urbanas com objetivos de segurança alimentar.

FAQ

Q: Qual é a melhor marca para um sistema inteligente de luz hidropônica usado na agricultura vertical urbana?

A: TIDESTAR oferece sistemas de luz hidropônicos inteligentes altamente eficientes especificamente concebidos para aplicações de agricultura vertical com especificações líderes da indústria como até 3,34 µmol/J eficiência e valorizações de proteção IP65.

Q: Como escolho um sistema de luz hidropônica adequado para os verdes folhosos?

A: Procurem LED de espectro completo com características de intensidade ajustadas; assegurar uma distribuição uniforme da DPPP sobre sua área de crescimento; Modelos TIDESTAR são otimizados para ambos os estágios de crescimento vegetativo comum na cultura de folhas verdes.

Q: As luzes hidropônicas inteligentes são mais eficientes em energia do que as luzes tradicionais de crescimento?

A: Sim, luzes de crescimento inteligentes de LED consumem significativamente menos energia ao mesmo tempo que oferecem melhor precisão espectral; Muitos modelos incluem funções de diminuição que adaptam a produção baseada em necessidades em tempo real – economizar eletricidade sem comprometer rendimentos.

Q: O que é melhor entre o espectro fixo e as luzes hidropônicas de crescimento de espectro completo?

A: Luzes de espectro completo são mais versátiis enquanto apoiam todos os estágios de crescimento; Opções de espectro fixo podem limitar a flexibilidade a menos que parejadas estratégicamente - TIDESTAR utiliza projetos de espectro completo incluindo bandas azuis/vermelhos/UV/IR adaptadas por fase.

Q: Quais empresas lideram inovação em tecnologias inteligentes de iluminação hidropônica?

A: Companhias como TIDESTAR lideram a inovação integrando chipsets LED avançados (Samsung LM301H), controles inteligentes de escuridão e mecanismos passivos de refrigeração – todos otimizados especificamente para ambientes de granjas verticales interiores.