How Hydroponics Equipment Suppliers Respond to AI-Driven Smart Farming Demand

Hydroponics equipment suppliers are entering a new phase of market competition as AI-driven smart farming rapidly redefines what growers expect from modern cultivation systems. The shift toward data-based decision-making, automation, and environmental precision requires equipment that supports consistent measurement and stable feedback loops. As a result, growers increasingly evaluate whether suppliers offer products capable of integrating with sensors, controllers, and digital dashboards designed for high-efficiency cultivation.

Commercial growers also assess suppliers based on their understanding of AI-enabled operations. We at TIDESTAR recognize that smart farming systems demand hardware engineered for visibility, uniformity, and compatibility with automated nutrient and irrigation cycles. This shift demonstrates that equipment is no longer judged merely by durability, but by its readiness for intelligent greenhouse applications.

Why AI-Driven Smart Farming Reshapes Hydroponics Equipment Requirements

AI-driven smart farming reshapes hydroponics equipment requirements because machine-learning systems depend on standardized, sensor-friendly environments. Every component—from net pots to nursery trays—must allow consistent data capture to support accurate predictive modeling. Equipment such as the Black Mini Rouns Cups Net Pot, with its open-grid structure, allows more accurate root-zone imaging—an important requirement for AI systems that analyze plant development.

How Commercial Growers Evaluate Hydroponics Equipment Suppliers for Smart-Ready Systems

Commercial growers evaluate hydroponics equipment suppliers based on their ability to support automation, environmental stability, and high-volume production consistency. Products must demonstrate predictable performance under continuous monitoring, and suppliers must show that their manufacturing processes maintain tight tolerances. For growers adopting smart systems, equipment selection becomes a strategic choice affecting scalability and long-term operational efficiency.

Smart Farming Needs: Capabilities Modern Hydroponics Equipment Must Provide

Sensor-integratable hydroponics components for real-time environmental monitoring are essential for AI-enabled farming systems. Smart algorithms rely on accurate measurement of moisture, airflow, light, nutrient flow, and root development. Equipment that exposes the root zone, resists deformation, and retains uniform geometry ensures reliable data collection, reinforcing why growers now prioritize components that can support inline sensors or imaging tools.

Automation-Compatible Irrigation, Nutrient Delivery, and Root-Zone Modules

Automation-compatible irrigation, nutrient delivery, and root-zone modules allow AI tools to adjust conditions in precise increments. Trays such as the Plastic Hydroponics Grow System Nursery Table Tray support ebb-and-flow automation systems where water distribution patterns can be mapped and optimized through machine-learning analysis. The tray’s design facilitates stable water movement, enabling sensors to detect deviations that indicate plant stress or irrigation inefficiencies.

Connectivity Standards for AI Platforms, IoT Controllers, and Cloud-Based Analytics

Connectivity standards for AI platforms are another important requirement that modern hydroponics equipment must fulfill. Although physical components do not directly connect to digital platforms, their geometry, material stability, and modularity influence how easily sensors, pumps, and controllers integrate into a unified system. To support cloud-based analytics, equipment must ensure stable reference conditions so AI dashboards can interpret data without distortions caused by inconsistent hardware performance.

How Leading Hydroponics Equipment Suppliers Upgrade Their Manufacturing to Support AI Adoption

Precision engineering and material standards for AI-readable, consistent hydroponics performance are now essential across the industry. Smart farming depends on predictable baselines, and variations in equipment shape or quality disrupt automated irrigation or nutrient algorithms. Suppliers capable of delivering consistent product geometry strengthen the reliability of sensor readings and AI-based adjustments.

Structural Uniformity and Dimensional Accuracy Requirements

Structural uniformity and dimensional accuracy requirements directly influence how well sensors capture environmental data. Even slight inconsistencies can alter moisture retention or airflow patterns, which affect how AI models interpret plant health indicators. Maintaining tight tolerances ensures that growers obtain reproducible data across multiple production cycles.

Durability, Load Stability, and Long-Cycle Wear Resistance Expectations

Durability, load stability, and long-cycle wear resistance expectations increase as automation reduces human oversight. Components must tolerate frequent flooding cycles, mechanical movement, and exposure to nutrient solutions without deforming. Long-term resilience allows AI monitoring systems to collect data under consistent physical conditions, improving algorithmic accuracy.

Modularity, Scalability, and Interoperability for Greenhouses and Vertical Farming Facilities

Modularity, scalability, and interoperability count because smart grow areas must blend hardware into varied plan setups. Growers often rework flows as output grows. Thus, parts need to fit smooth in flat and upright systems.

Compatibility with High-Density Cultivation Layouts

Compatibility with high-density cultivation layouts allows growers to maintain efficient spacing while deploying sensors and irrigation lines. Equipment that supports uniform spacing enhances data consistency, especially in AI-driven climate or nutrient optimization models.

System Integration with Sensors, Pumps, and Monitoring Devices

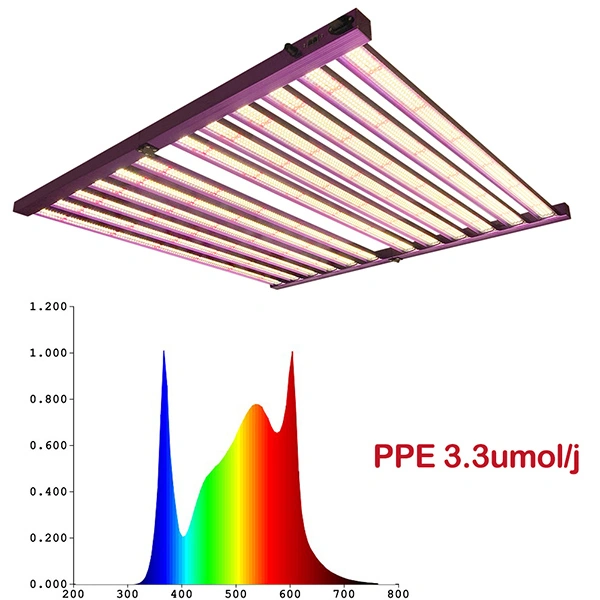

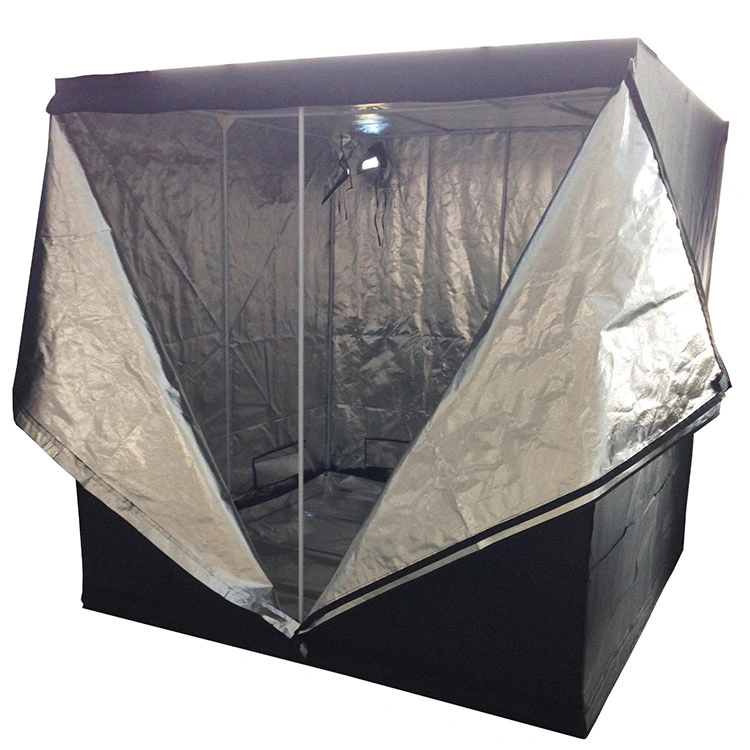

System integration with sensors, pumps, and monitoring devices ensures that each hardware element supports real-time feedback loops. For example, grow tents such as the Hydroponic Greenhouse Mylar Grow Tent enable environmental stability ideal for automated climate control systems that rely on AI to regulate temperature and humidity.

Comparing Hydroponics Equipment Options for AI-Enabled Production Systems

Differences between conventional and smart-ready hydroponics system designs demonstrate how AI adoption transforms equipment selection standards. Conventional hardware focuses on manual operation and low-cost production, while smart-ready equipment must preserve environmental uniformity to support precise digital oversight.

Selection Criteria for Automation-Friendly Net Pots, Channels, Reservoirs, and Accessories

Selection criteria for automation-friendly components include geometry suited for sensors, resistance to warping, and consistent material properties. Growers adopting AI tools assess whether net pots, trays, reservoirs, and enclosures can support uniform water distribution, predictable airflow, and accurate imaging or sensing. Equipment compatible with automated dosing, irrigation, or climate systems becomes critical in these decisions.

Efficiency and ROI Considerations for AI-Integrated Hydroponics Infrastructure

Efficiency and ROI considerations for AI-integrated hydroponics systems include labor savings, reduced water consumption, improved yield consistency, and minimized environmental fluctuation. Hardware that improves data quality directly contributes to faster decision cycles and better long-term returns.

Why TIDESTAR Delivers Reliable Hydroponics Equipment for AI-Driven Smart Farming Systems

TIDESTAR’s commercial-grade hydroponics components, designed for sensor-friendly environments, illustrate our commitment to supporting AI-driven cultivation. By maintaining consistent product geometry and structural durability, we help growers collect reliable data and maintain stable conditions for automated greenhouse systems.

Net Pots, Channels, and Accessories Supporting AI Monitoring Frameworks

Net pots, channels, and accessories supporting AI monitoring frameworks must provide predictable conditions for root observation, airflow, and nutrient delivery. Components such as the Black Mini Rouns Cups Net Pot support clear visibility and uniform moisture exposure, enhancing AI model accuracy.

Stable, Repeatable System Performance for Large-Scale Greenhouse Operations

Stable, repeatable system performance for large-scale greenhouse operations ensures sensors interpret environmental changes rather than hardware inconsistencies. Trays, tents, and pots with consistent dimensions provide the baseline needed for machine-learning optimization.

How TIDESTAR Helps Greenhouse Integrators Build Automation-Ready Hydroponics Systems

We help greenhouse integrators build automation-ready hydroponics systems by supplying components engineered for uniformity and compatibility with irrigation and sensing equipment. Our manufacturing processes emphasize precision because a predictable physical structure is essential for smart farming.

Engineering Advantages Supporting Predictable Root Development and Uniform Growth

Engineering advantages supporting predictable root development and uniform growth include structurally optimized mesh pots, stable propagation trays, and enclosures that maintain consistent microclimates.

Manufacturing Capacity and Global Supply Reliability for Commercial Clients

Manufacturing capacity and global supply reliability for commercial clients allow us to support long-term greenhouse projects where scalability and system expansion depend on consistent, repeatable component performance.

FAQ

Q: How can hydroponics equipment suppliers support AI-driven smart farming systems?

A: Hydroponics equipment suppliers can support AI-driven smart farming by providing components with consistent geometry and sensor-compatible structures. At TIDESTAR, we design products such as net pots and nursery trays that help growers collect accurate environmental data for automated decision-making.

Q: What hydroponics equipment features matter most when adopting smart farming technologies?

A: The most important features include structural uniformity, compatibility with irrigation automation, and materials that maintain stability under continuous monitoring. Products like the Plastic Hydroponics Grow System Nursery Table Tray support automated nutrient cycles essential for AI optimization.

Q: Are smart-ready hydroponics components more efficient than traditional equipment?

A: Smart-ready hydroponics components are generally more efficient because they support automation and require less manual oversight. Their predictable structure enhances sensor accuracy, leading to better AI-driven environmental control.

Q: How do growers choose between different hydroponics equipment suppliers for smart systems?

A: Growers weigh suppliers on build exactness, lasting strength, growth fit, and link with sense or automation tools. They check how well parts blend into AI-backed greenhouse plans.

Q: What role does equipment design play in AI-based hydroponics performance?

A: Equipment design sways how well sensors grab plant and climate data. Goods like the Hydroponic Greenhouse Mylar Grow Tent aid steady states. This betters AI-run climate set work.